Services

Integrated Project Management

End‑to‑end management that aligns people, processes, and technology from FEED to delivery—focused on efficiency, safety, and cost control.

Project Planning & Execution

Rigorous planning, clear milestones, and disciplined execution to deliver on time and on budget.

Well Engineering & Design

Customized drilling/completion designs aligned to subsurface realities and operational constraints.

Operations Optimization

Root‑cause analysis and performance improvements that measurably reduce NPT.

Logistics & Supply Chain

Coordinated movement of people, tools, and materials for onshore/offshore operations.

Vendor & OEM Partnerships

Global technology access with local execution and cost efficiency.

HSE & Risk Management

Safety culture, compliance, and proactive risk controls embedded in every phase.

Front End Engineering Design (FEED)

Cost‑effective, practical designs across the well life cycle—from planning and execution to long‑term production and integrity.

- Well design & schematics tailored to the field

- Completion strategy development for efficiency and cost

- Materials & equipment selection for durability and compliance

- Cost & risk analysis to surface savings opportunities

- Lifecycle planning that preserves asset integrity

Design Principles

“Smart designs today for wells that last tomorrow.”

Right‑sized solutions that balance risk and return

Rooted in best practices and operational reality.

From first oil to decommissioning.

Reservoir Modelling & Geomechanical Services

Integrating seismic, petrophysical, and geological data with advanced simulation to predict performance and guide development.

Static & Dynamic Models

3D reservoir properties and flow behavior under various scenarios.

Petrophysical & Geological Integration

Data‑driven reservoir characterization and uncertainty handling.

Production Forecasting

Scenario planning to optimize recovery and well placement.

Geomechanical Modelling

Stress, pore pressure, fracture gradients & sanding prediction.

Wellbore Stability

Design and drilling practices to reduce risk and NPT.

Reservoir Management

Field development and depletion strategies anchored in data.

Well Intervention & Integrity

Boost production, restore declining wells, and safeguard long‑term performance with wireline, CTU, stimulation, and P&A support.

- Well diagnostics to pinpoint integrity and performance issues

- Production enhancement via stimulation and remedial work

- Wireline & coiled‑tubing interventions

- Proactive integrity monitoring & management programs

- Safe, compliant plug & abandonment

“From first production to final plug, we keep your wells performing.”

Value Outcomes

Faster issue resolution and planned interventions.

Stability through monitoring and preventative work.

HSE‑led execution across the lifecycle.

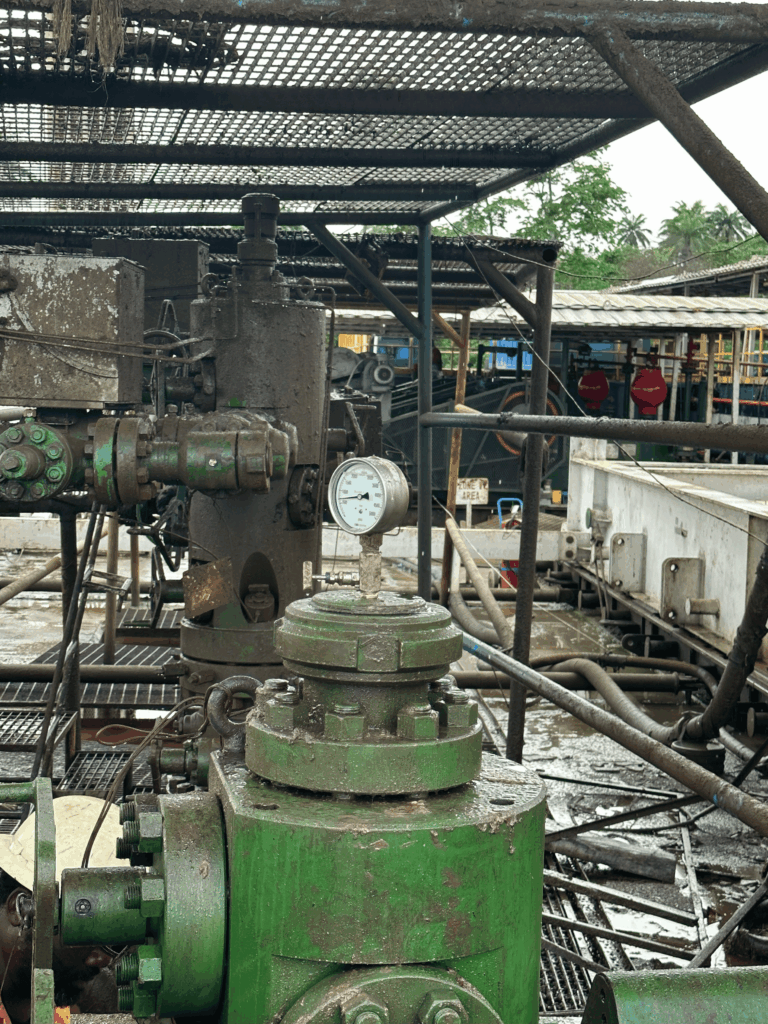

Rig Management Service

Maximize Uptime. Optimize Performance. Enhance Profitability.

At KOSAM Integrated, we deliver comprehensive Rig Management Services tailored to unlock the full potential of your drilling assets. From day-to-day operations to long-term performance optimization, our experienced team ensures your rigs operate at peak efficiency — safely and reliably.

- Daily rig operations oversight

- Preventive and corrective maintenance

- Logistics coordination

- Technical performance optimization

- Cost control and smart asset management

With a focus on safety, efficiency, and profit-driven results, we transform underperforming rigs into high-value assets. Partner with KOSAM Integrated to take control of your rig’s future and get the most from your investment.